Why the right machine makes all the difference in manufacturing

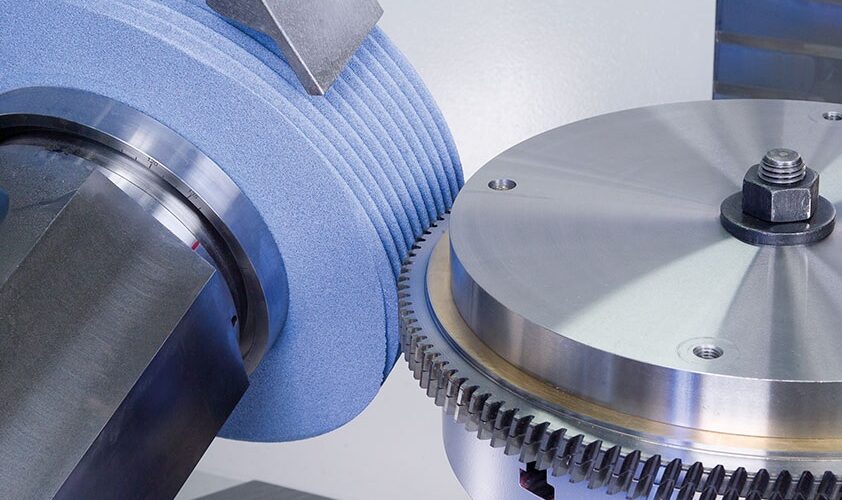

In the world of precision engineering, the ability to achieve consistent, smooth, and accurate finishes is vital. Whether it’s aerospace components, automotive parts, or custom industrial tools, manufacturers depend on grinding machines to produce surfaces that meet tight tolerances and demanding specifications.

But not all grinding equipment is created equal. Choosing the right machine for grinding can have a significant impact on the quality, efficiency, and cost-effectiveness of your operations.

What Is a Grinding Machine?

A grinding machine is a type of tool used to shape or finish materials, typically metal, by using abrasion. The grinding process removes small amounts of material through friction between a rotating wheel and the workpiece. It’s especially useful for producing surfaces that require high precision and excellent finishes.

Grinding machines come in many forms, including:

- Surface grinders

- Cylindrical grinders

- Centreless grinders

- Internal grinders

Each type is suited to specific applications, depending on the shape, size, and complexity of the component being worked on.

Key Benefits of Using a Grinding Machine

- High Precision and Accuracy

Modern grinding machines are capable of achieving extremely tight tolerances, often within microns. This level of accuracy is essential for industries like medical, aerospace, and automotive manufacturing, where even the slightest deviation can lead to performance issues or component failure.

- Superior Surface Finish

Grinding delivers an incredibly smooth finish that can’t always be achieved through milling or turning. This is crucial for parts that need to reduce friction or fit seamlessly with other components.

- Material Versatility

A reliable grinding machine can handle a wide range of materials including steel, stainless steel, titanium, aluminium, and certain plastics. This flexibility makes grinding a go-to process in multi-material production environments.

- Enhanced Efficiency

Using the right machine reduces downtime and increases throughput. When components are finished correctly the first time, there’s less need for rework, and production schedules remain on track.

Choosing the Right Machine for Grinding

The optimal machine depends on several factors:

- Shape and size of the workpiece: Flat parts call for surface grinding, while cylindrical parts benefit from cylindrical or centreless grinders.

- Required surface finish: Higher finishes may need finer wheels and more controlled passes.

- Production volume: Some machines are better suited to high-volume automated production, while others cater to low-volume, high-precision work.

Working with a specialist provider ensures you get the right match between your project needs and the machine’s capabilities.

Why Work with an Expert Grinding Service?

Even the best machine requires skilled operators and the right support. That’s where companies like West Midland Grinding come in. With decades of experience and a full suite of grinding machines in-house, they offer everything from one-off precision grinding to batch production and surface finishing.

Their team can recommend the most suitable machine for grinding based on your drawings, specifications, and performance requirements — ensuring your components meet the highest standards.

Final Thoughts

Precision grinding plays a critical role in modern manufacturing, and investing in the right equipment or working with the right partner can significantly improve your production outcomes. From enhanced tolerances and better finishes to reduced costs and increased efficiency, the benefits of a suitable machine for grinding are clear.

If your business relies on accurate, smooth, and dependable components, consider partnering with a specialist like West Midland Grinding to get the job done right.